Test Results

Bright Lite Structures' patented, low-cost recycled thermoset and thermoplastic solutions enable our components to meet aerospace and rail fire, smoke, toxicity, heat release, HIC and 16g requirements. It avoids weight and strength issues associated with aluminum and phenolic composites, as well as the cost issues associated with traditional thermoplastics. BLS thermoset and thermoplastic solutions also enable it to meet heat and sound insulation requirements.

BLS patented thermoset and thermoplastic technology meets:

- • Aerospace FAR 25.853 for Flammability, Smoke Emission, Toxicity & OSU Heat Release aerospace requirements.

- • EN 45545-2:2014 + A1: 2015 for HL1 and HL2 Hazard Level Classification for rail R1 and R7 requirements.

- • ISO Section 8.3, 1496-2:2018 requirements for intermodal freight containers.

AEROSPACE

FAR 25.853

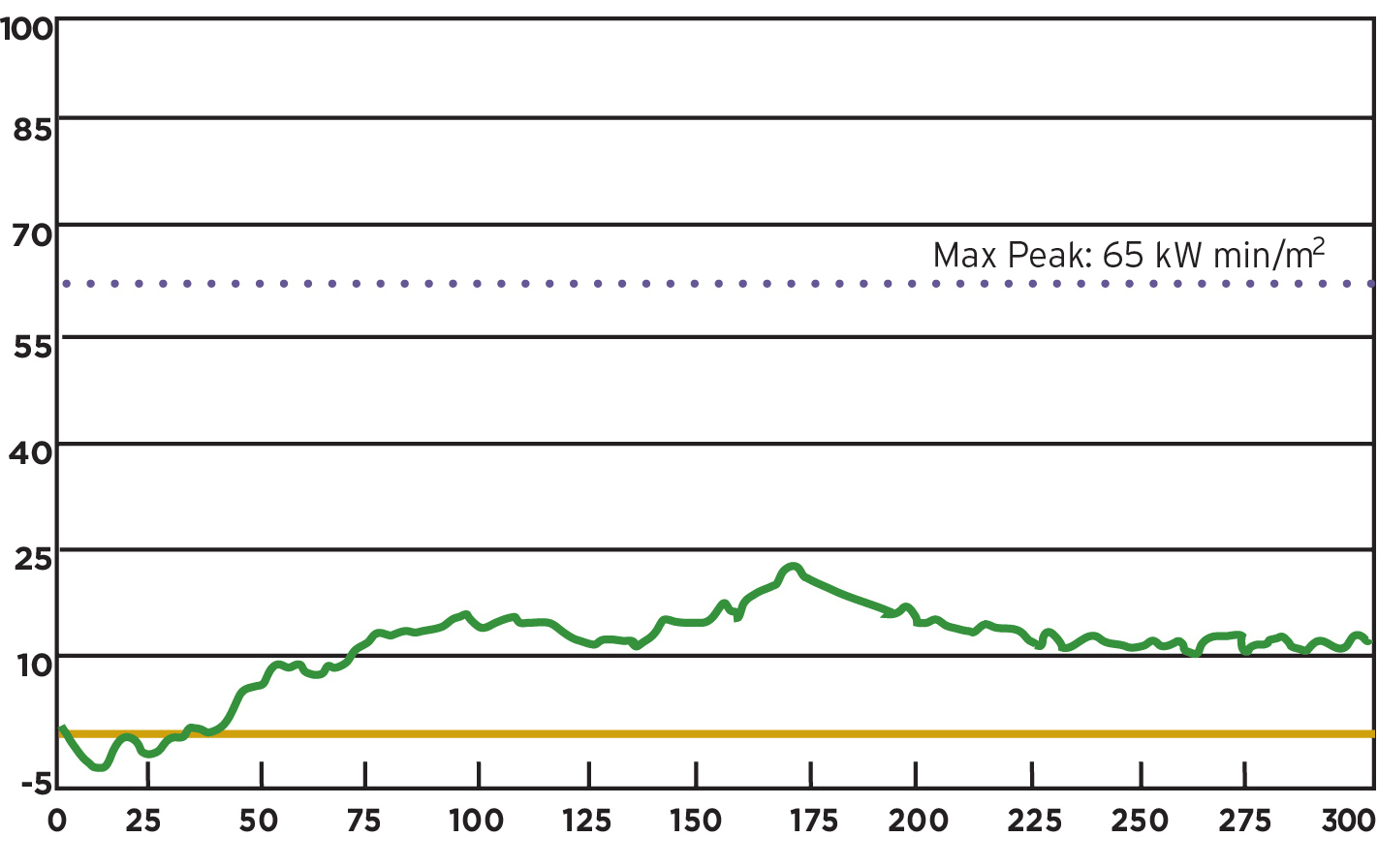

OSU Heat Release

Maximum rate of heat release: 20.9

Time of Peak: 167

Two minute total: 15.8

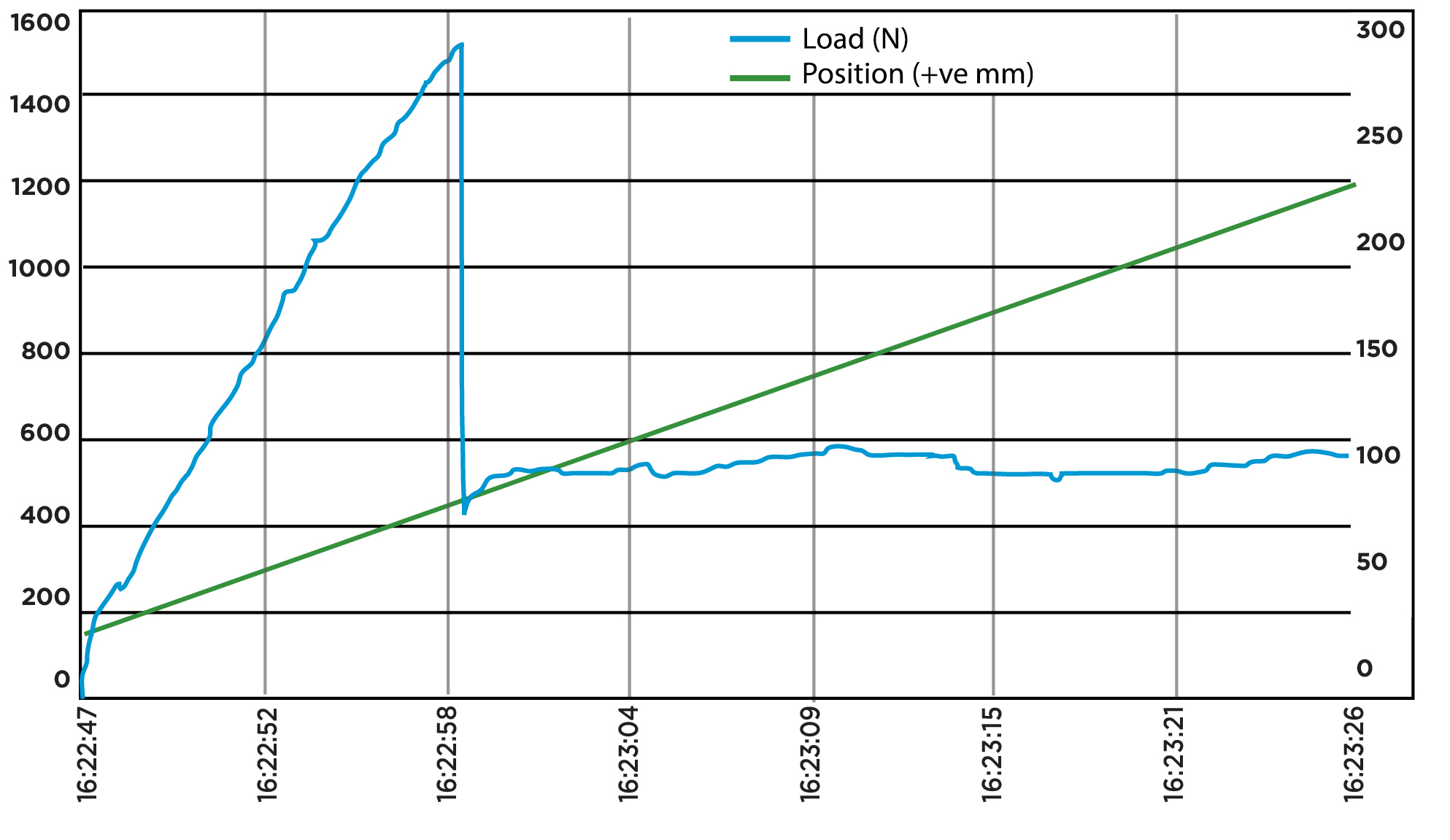

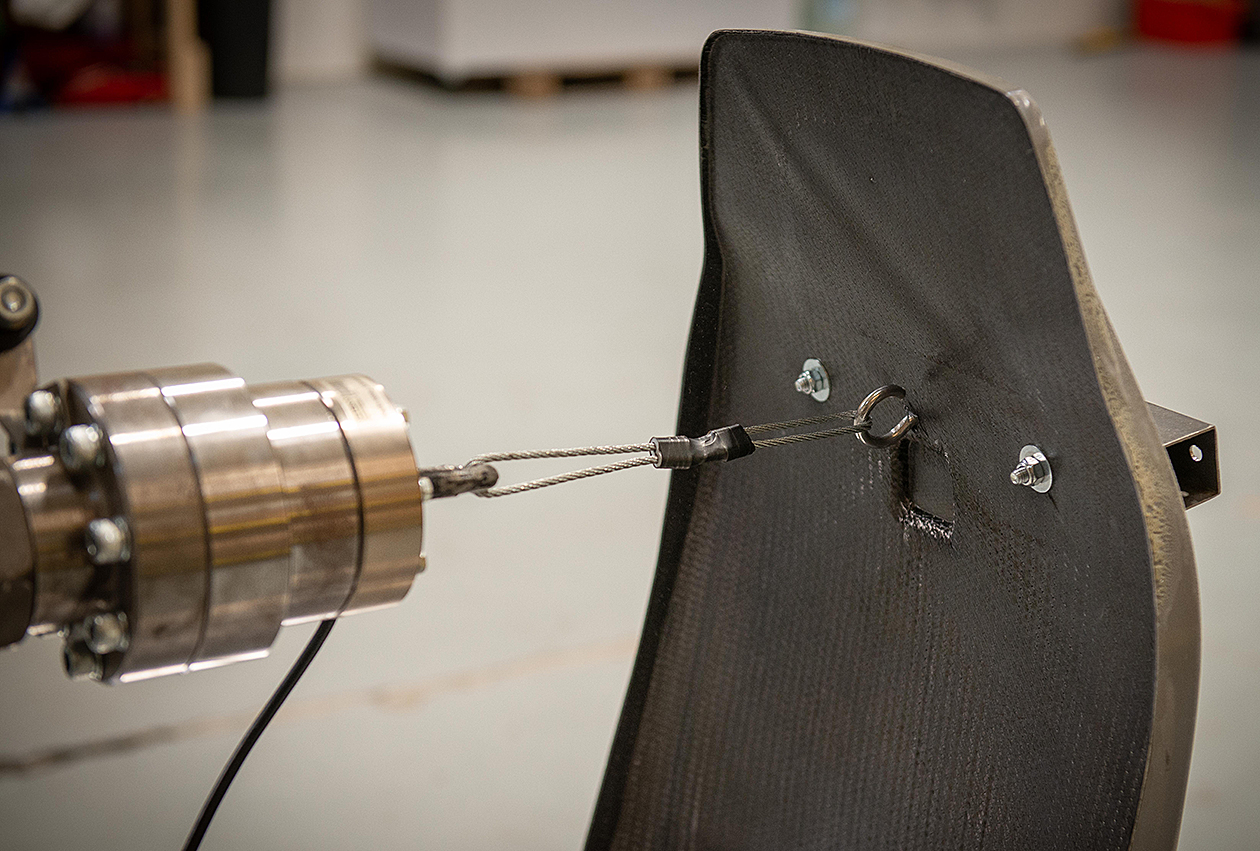

EASA/FAA HIC & 16G Testing

Graph is Load (N) & Position (mm) against Time

Max: 1500.93 N

RAIL

EN 45545-2: 2013 + A1: 2015 for HL1 & HL2

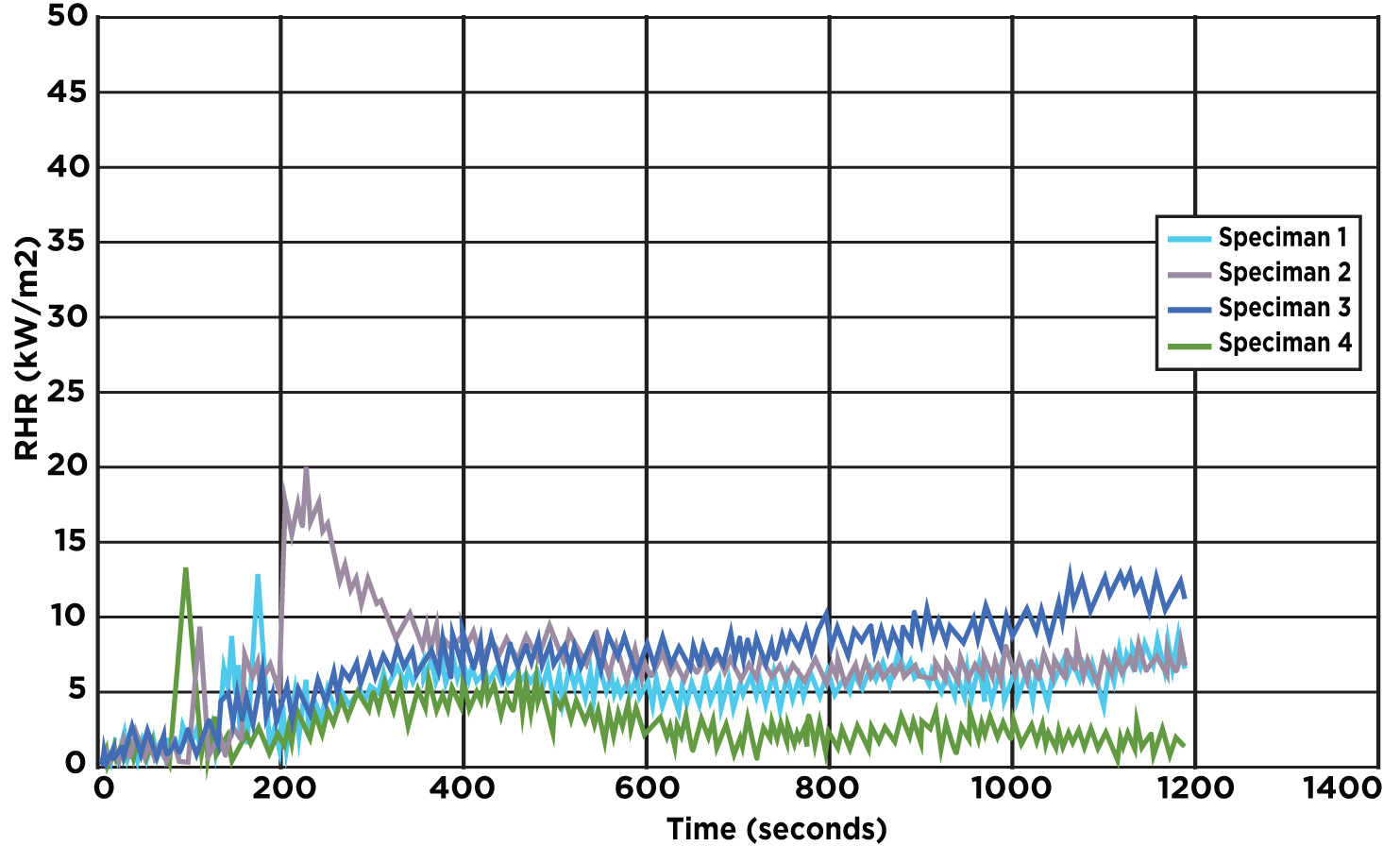

Heat Release Test Result

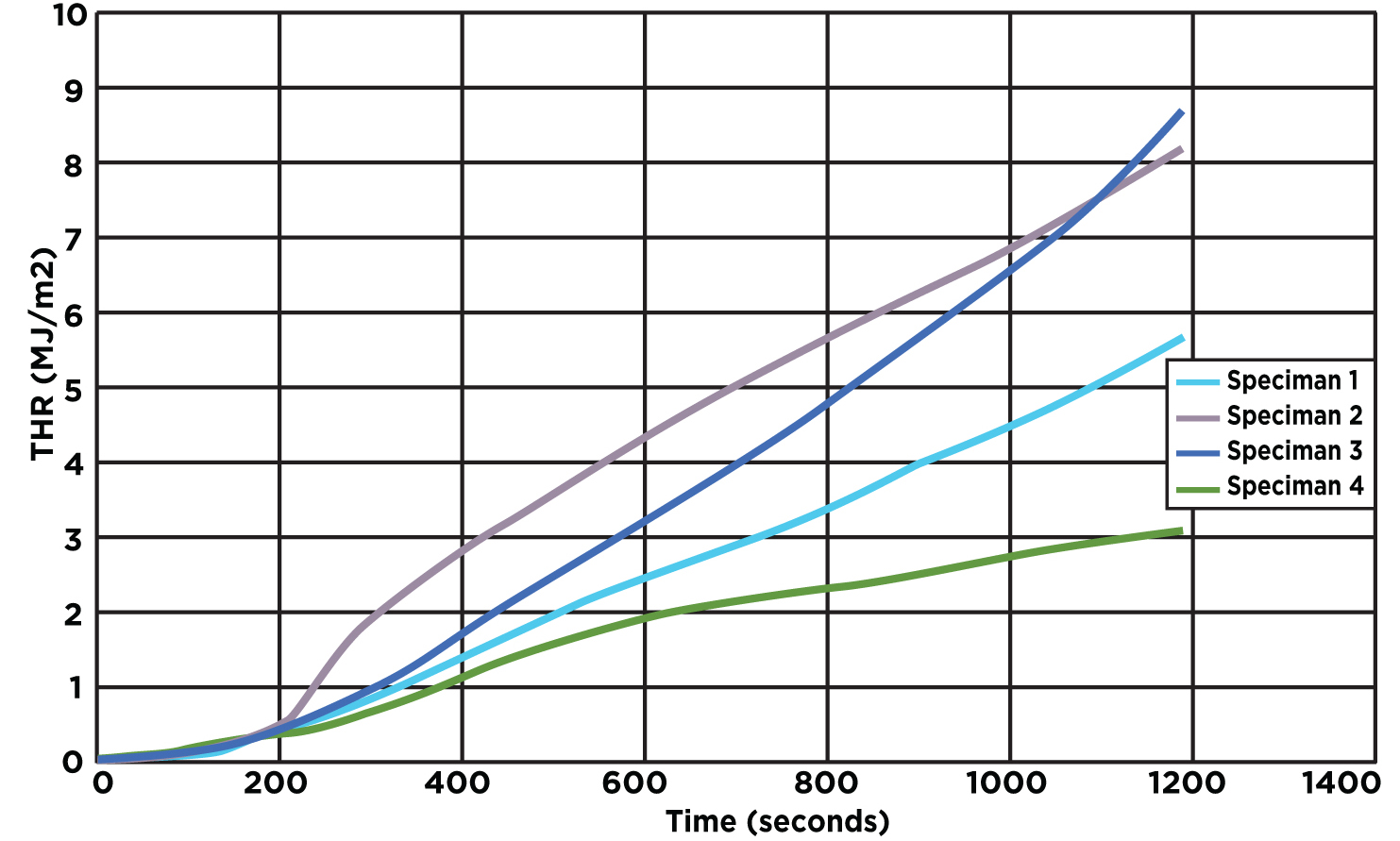

Total Heat Release Test Result

FREIGHT

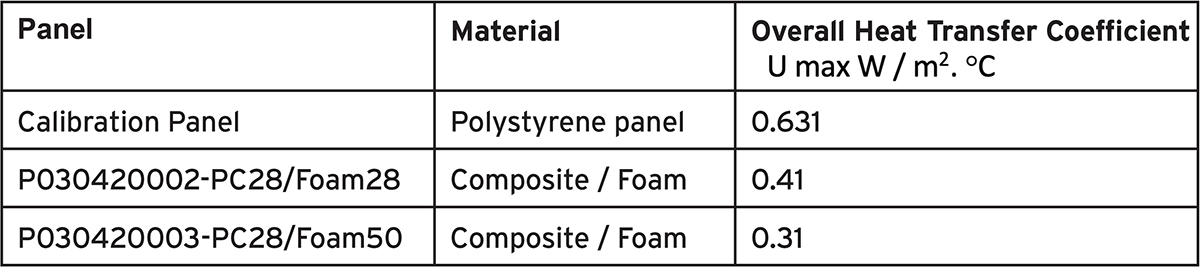

ISO Section 8.3, 1496-2:2018 Thermal Insulation Testing

Testing was done for maximum heat transfer rate (U max) for intermodal freight containers. BLS composite panels were compared with a calibration sample of 76mm thick polystrene panel.

Summary Results