Facilities Overview

Facilities & Equipment

Bright Lite Structures (BLS) occupies two facilities totaling more than 60,000 square feet in Stamford, UK. These facilities house its UK offices and design and prototyping departments, as well as full manufacturing, post-production, and quality control.

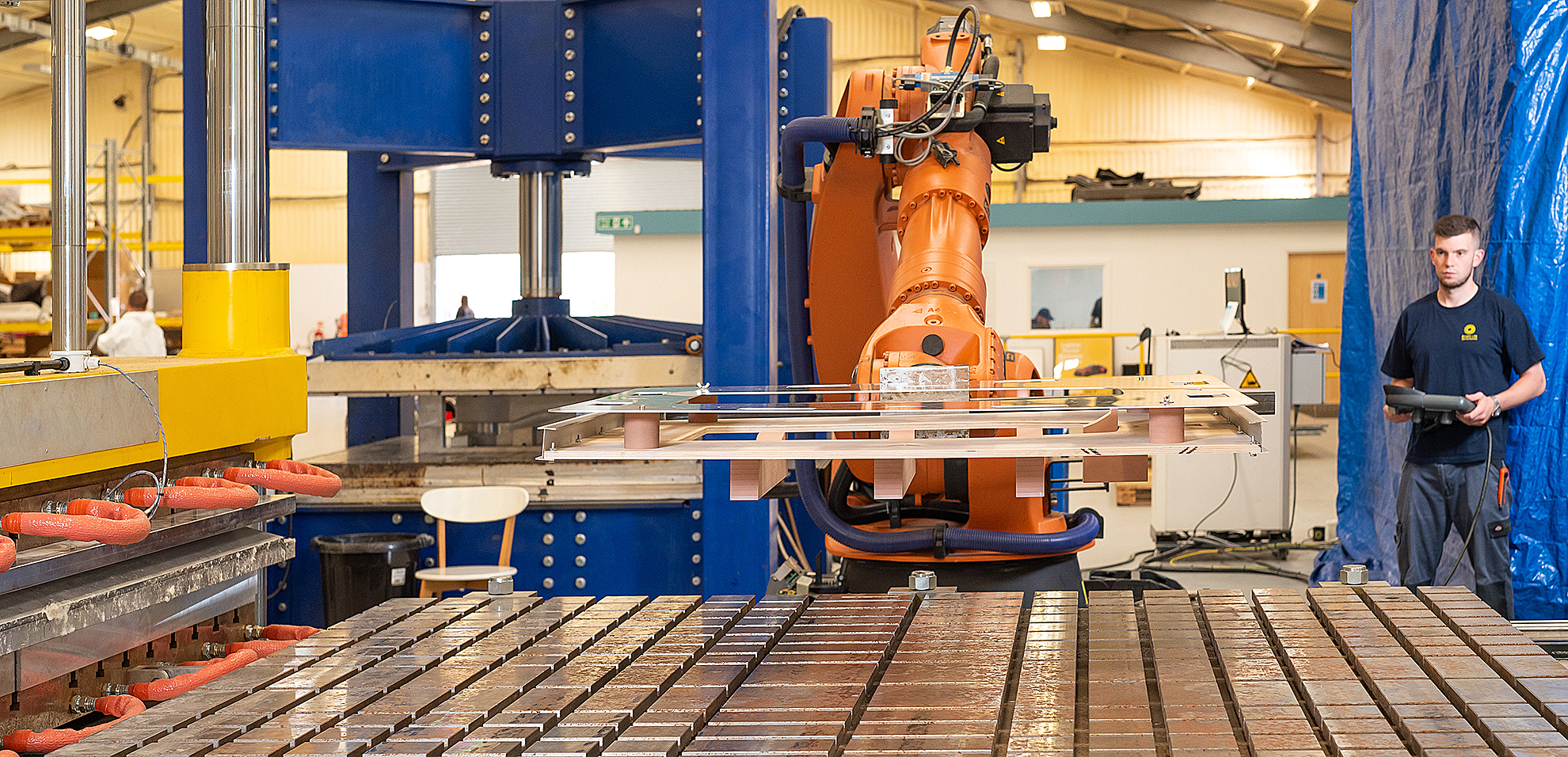

Our extensive manufacturing equipment includes five presses, the largest of which, to be delivered in early 2022, will feature a 3.6 meter bed. BLS has several robotized Hennecke and AutoRIM spray systems used in automated production, as well as separate robotized trim cells and post curing facilities. This system is supported by additional robots for material handling.

Extensive R&D facilities are also housed within the BLS facilities. These include presses, and equipment for stress and materials testing, among other tools.

Depending on the size of the components, BLS has press capacity in excess of 40,000-100,000 units per annum. Capacity can be more than doubled within a year. BLS has ISO:9001 2015 accreditation for the concept, design, development, prototyping, and production of advanced composite components.

Quality-Control Systems

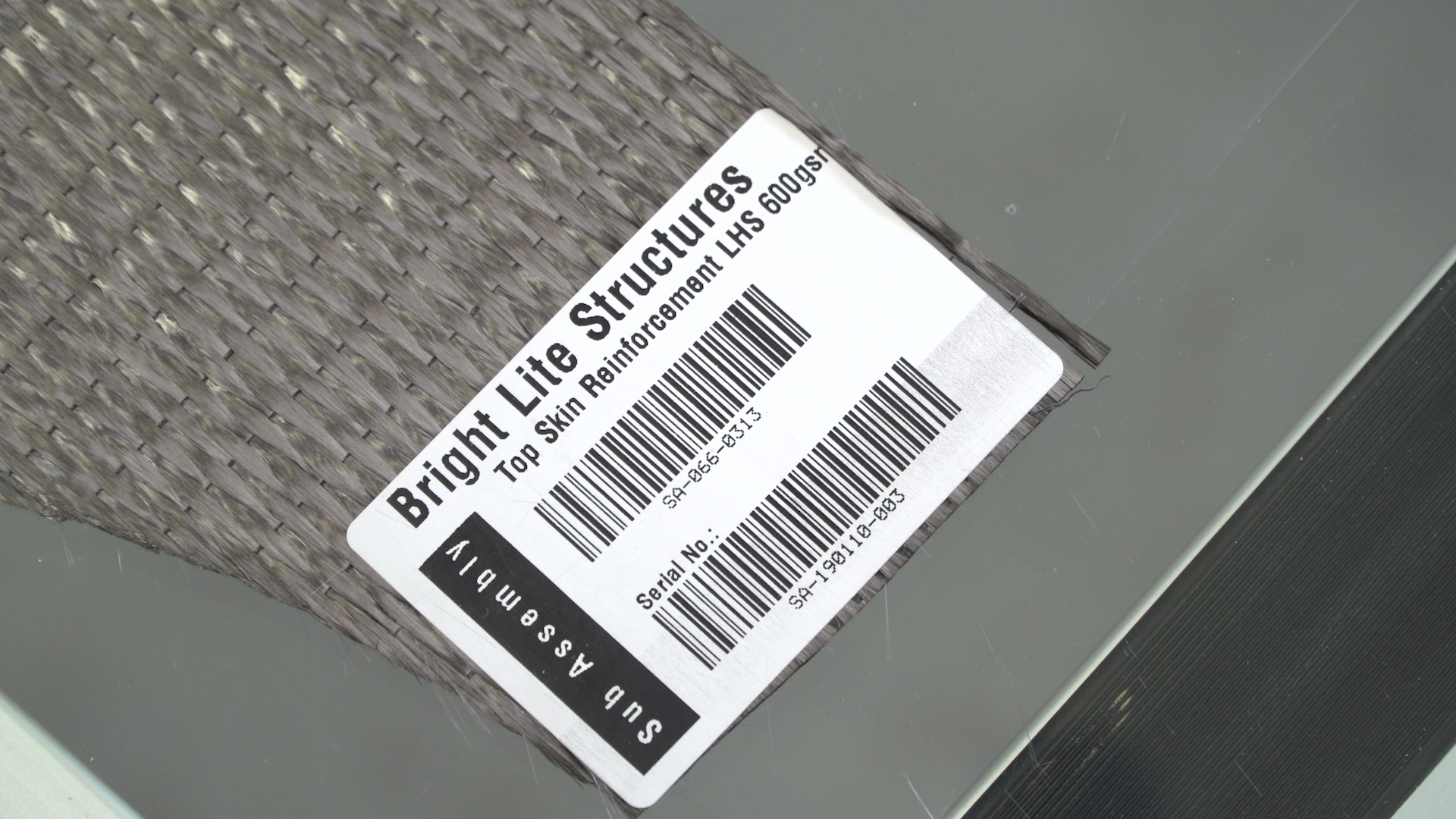

To maintain full traceability within the manufacturing process, BLS uses an industry leading production management system. Using RFID tags in each assembly, materials and processes are tracked and digitally stored from initial raw component delivery throughout the complete manufacturing process.

Product quality requirements are defined and agreed upon with the customer at the outset of each project. Throughout commercial production, these standards are continually monitored and maintained. Our goal is to continually improve our quality and services to ensure that our product meets the highest standards.