Automotive Chassis & Structural Elements

Objective: Design and manufacture chassis and structural components that are light-weight, stiff and pass all crash test requirements. Be cost competitive and environmentally friendly, and meet high-volume requirements.

BLS Solution

- • Created weight savings

- • Created fuel savings

- • Reduced part count (BOM) and assembly cost

- • Fatigue tested to meet stiffness requirements

- • Molded construction created complex shapes

- • Combined recycled carbon fiber and recycled polycarbonate core

- • Cost competitive with aluminum

- • Helps meet EU CO2 requirements

- • Required less capital investment

- • Provides good sound and heat insulation

- • Manufactured in volumes from 100 to 50,000

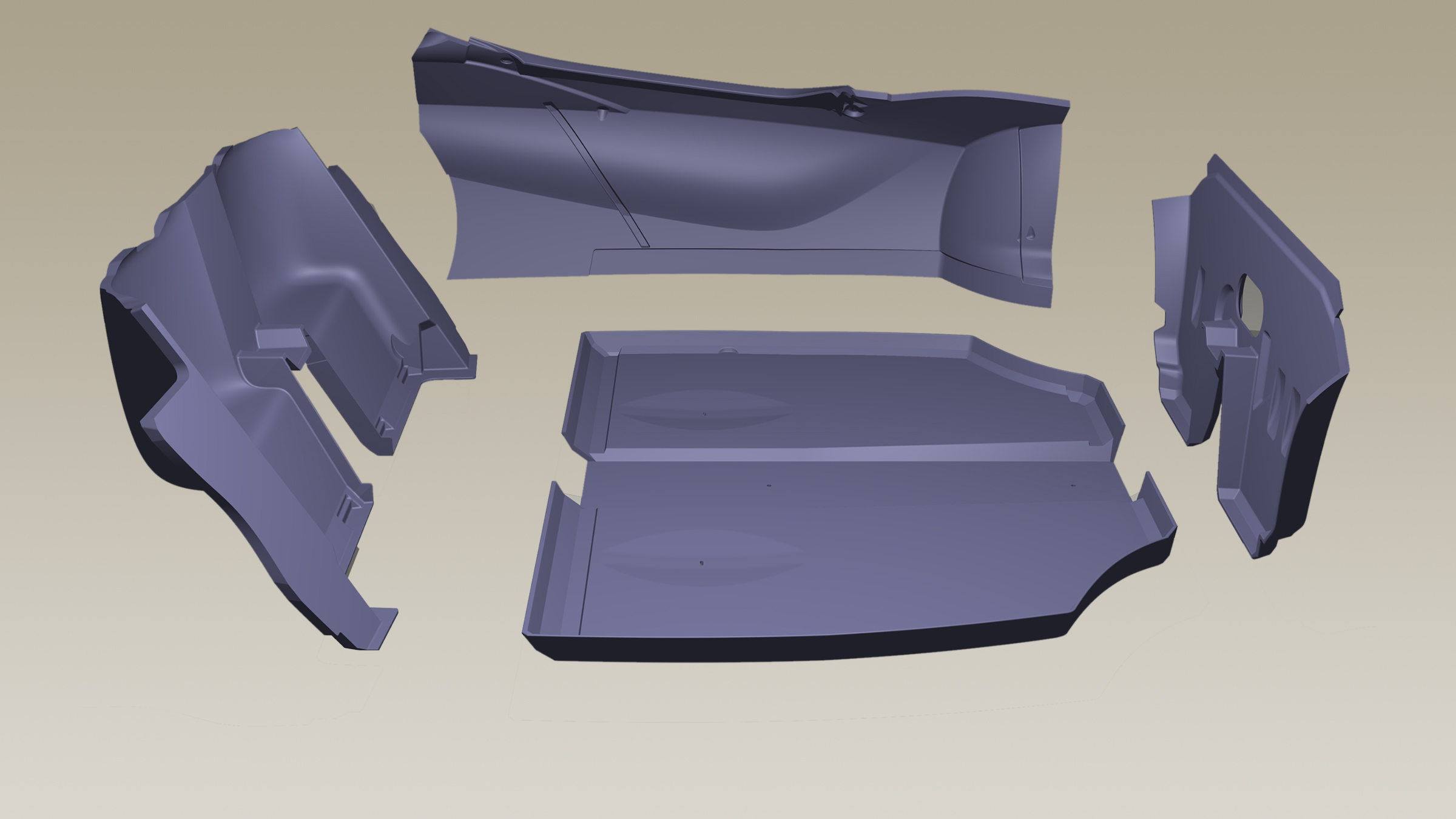

The BLS designed Zenos chassis is made of only five parts. Second side panel not shown in this cut-away.

The chassis is self-jigging, substantially reducing assembly time and costs.

The Zenos E10 with BLS chassis. BLS components can have a Class A finish. This permits components to be used on the exterior, seen here on the door panel.

How did we make a strong, light-weight five-piece chassis for this sports car? Check out this short video and see why our composite technology is better than conventional carbon.