BLS Compared with Commonly Used Materials

Lighter

- • Up to 50% lighter than steel

- • Up to 35% lighter than aluminum

- • Up to 20% lighter than conventional composites

Stiffer

- • High compression, stiffness, and torsional rigidity values

- • Most suitable where application is stiffness or compression driven

- • Stiffer than conventional composites

Faster

- • Process can shorten the production cycle from 45 minutes to under 5 minutes

- • No pre-forming required

Less Expensive

- • Reduced material costs; combines recycled & continuous carbon fiber

- • Uses less carbon fiber

- • Lower tooling costs

Complex Forms

- • Forms 90° bends with zero draft angle

- • Deep draws obtainable

- • Independently shaped sides

- • No spring-back

Larger Parts

- • BLS low-pressure presses can produce larger individual components

- • Thickness variable on either side of sandwich structure

It's lighter-weight, stiffer and more flexible than conventional composites

A Simple, Single Step Manufacturing Process

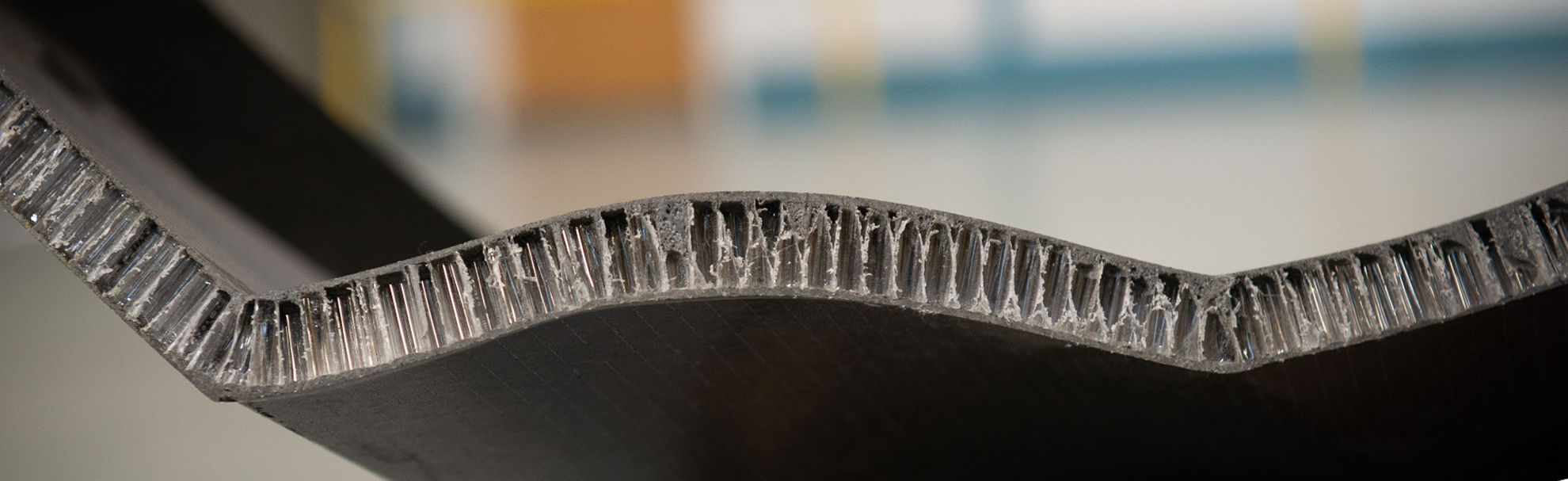

The patented BLS composite technology uses a sandwich construction, where the top and bottom fabric layer of recycled and continuous carbon fiber surround a central core of recycled polycarbonate honeycomb.

The fabric sides are impregnated with BLS patented resins. This flat, honeycomb sandwich panel is then wet-compression molded in a hot tool, allowing deep-draw and complex designs in one step without pre-forming. The process simultaneously thermo-forms the core and cures the resins, reducing manufacturing steps and lowering costs. Once released from the mold, components are self-jigging and easily bonded together.

This approach requires less resin and less carbon fiber than conventional composites which combines to cut total material costs, and produces significantly less material waste in the process.

The sandwich construction meets or exceeds many industry compression, stiffness, and torsion rigidity requirements. It also significantly reduces component weight by 25–50% compared with competitive materials in aerospace, commercial vehicle, rail, automotive, and other industrial applications.

Components made from the BLS process, using less carbon fiber in combination with recycled polycarbonate, cost appreciably less than those using exclusively continuous and monolithic materials.